Industrial and Commercial Water Softeners For Limescale Removal

Introduction:

When water is hard, it can clog pipes, damage boilers, heat exchangers, and many other devices. Water softening can prevent these negative effects. Hard water causes a higher risk of lime scale deposits in industrial, commercial and household water systems.

Due to this lime scale build-up, pipes are blocked and the efficiency of hot boilers and tanks is reduced. This increases the cost of domestic water heating by about fifteen to twenty percent.

Another negative effect of lime scale is that it has damaging effects on commercial machinery, such as laundry machines. Water softening using a water softener system expands the life span of each machine. It also contributes to the improved working, and longer lifespan of solar heating systems, air conditioning units and many other water-reliant systems.

What do water softeners do?

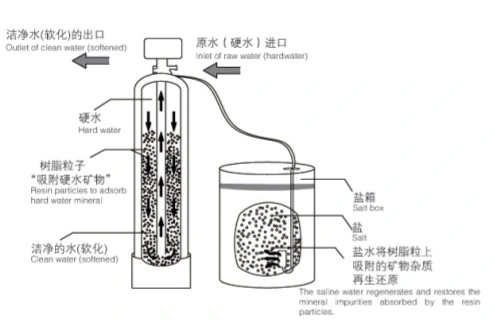

Industrial water softeners are specific ion exchangers that are designed to remove ions which are positively charged.

Softeners mainly remove calcium (Ca2+) and magnesium (Mg2+) ions. Calcium and magnesium are often referred to as "hardness minerals". Softeners are sometimes even applied to remove iron.

The softening devices are able to remove up to five milligrams per liter (5 mg/L) of dissolved iron and can operate automatic, semi-automatic, or manual. Each type is rated on the amount of hardness it can remove before regeneration is necessary. Commercial water softeners collect hardness minerals within its conditioning tank and from time to time flushes them away to drain.

When an ion exchanger is applied for water softening, it will replace the calcium and magnesium ions in the water with other ions, for instance sodium or potassium. The exchanger ions are added to the ion exchanger reservoir as sodium and potassium salts (NaCl and KCl).

How long does a water softener last?

A good water softener system will last many years. Water softeners that were supplied in the 1980's may still work, and many need little maintenance, besides filling them with salt occasionally.

How often should one add salt to a softener?

Salt is usually added to the reservoir during regeneration of the softener. The more often a softener is regenerated, the more often salt needs to be added. Usually water softeners are checked twice a month and to guarantee a satisfactory production of soft water, the salt level should be kept at least half-full at all times.

Technical parameters:

| Category | Model | Recommended water yield (M³/h) | Tank size Diameter *Height(mm) | Salt box (L) | Amount of resin(KG) |

| Dual-valve and dual-tank (simultaneous operation and respective regeneration) | YL-II-36 | 24-36 | 900×1900 | 800 | 1040 |

| YL-II-50 | 36-50 | 1000×2200 | 1000 | 1440 | |

| YL-II-70 | 50-70 | 1200×2400 | 1500 | 2000 | |

| YL-II-100 | 70-100 | 1500×2500 | 2000 | 3200 | |

Dual-valve and dual-tank(One for use and the other for standby) | YL-II-1 | 1 | 250×1400 | 60 | 80 |

| YL-II-2 | 2 | 300×1400 | 100 | 120 | |

| YL-II-3 | 3 | 350×1400 | 100 | 160 | |

| YL-II-4 | 4 | 400×1650 | 200 | 240 | |

| YL-II-5 | 5 | 500×1750 | 300 | 360 | |

| YL-II-6 | 6 | 600×1900 | 350 | 480 | |

| YL-II-10 | 8-10 | 750×1900 | 500 | 720 | |

| YL-II-18 | 12-18 | 900×1900 | 800 | 1040 | |

| YL-II-25 | 18-25 | 1000×2200 | 1000 | 1440 | |

| YL-II-35 | 25-35 | 1200×2400 | 1500 | 2000 | |

| YL-II-50 | 35-50 | 1500×2500 | 2000 | 3200 |