Yida redispersible latex powder (VAE/RDP) YD1060 is a redispersible latex powder formed by spray drying of ethylene and vinyl acetate copolymer emulsion designed with flexible end groups. This product has good resolubility and good flexibility after film formation; it can effectively improve the sealing, impermeability, water resistance, frost resistance and weather resistance of the mortar.

YD1060 is widely used in interface agents, caulking agents, thermal insulation mortar, flexible putty, gypsum-based products, tile adhesives.

Physical And Chemical Properties

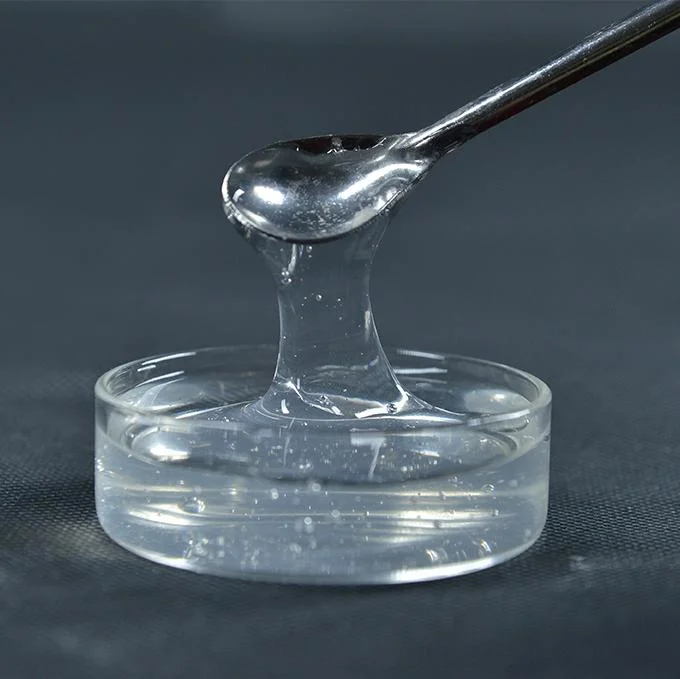

(1)Redispersible latex powder is easily soluble in water and easy to form emulsion.

(2) Redispersible latex powder has strong cohesive force and good tensile force.

(3) Redispersible latex powder can improve the processability, flexibility and impermeability of materials.

(4) Redispersible latex powder can improve the cohesion of the mortar, increase the concentration and anti-sagging.

(5) Redispersible latex powder can improve the flexibility of the mortar and extend the open time.

Other ApplicationsRedispersible latex powder is widely used in

★external wall insulation systems,

★tile adhesives,

★joint fillers,

★self-leveling mortar,

★repair mortar,

★putty,

★decorative mortar,

★diatom mud,

★waterproof slurry,

★wear-resistant floor

★other fields.

| Polymer composition | VAC/E |

| Appearance | White powder can flow freely |

| Solid content,% | ≥98.0 |

| Ash content,% | 13±2 |

| Stacking density,g/l³ | 400-600 |

| Average grain diameter,μm | 80-120 |

| PH Value | 6-8 |

| Film-forming temperature,ºC | 0-5 |

The recommended dosage of this product is 3-20‰ of the system, and the dosage needs to be determined by experiment.

Production Process

Ethylene-vinyl acetate rubber powder (VAE-RDP) is made of vinyl acetate/ethylene copolymer emulsion (EVA emulsion) modified by adding water-soluble protective colloid (polyvinyl alcohol usually PVA) and spray-dried, using water as the medium Can be re-formed into an emulsion, a powder with redispersibility.

Packaging & Storage★Packages: PP bag with inner PE bag, Net Weight: 25 kgs

★Storage: After the product is opened and used, it must be sealed in time. This product is thermoplastic, so it should be stored in a high-temperature environment to avoid pressure.

Otherwise, it will easily cause agglomeration.

Sealed and stored in a cool and dry place at 0-40ºC, and the storage time should not exceed 24 months.

★Shipping: Shipping as non-danger goods.

Our Advantages

1- German horizontal kettle "one-step" production technology, quality products.

2- Factory direct supply, fast delivery, and timely follow-up.

Service

1- Professional construction-grade cellulose ether supplier.

2- Construction chemicals and technology solutions provider.

3- Free formulations for construction grout mortar.

Technical Support

During the preparation of various formula systems for this product, the Yida technical team can provide technical consultation, technical tracking, and long-term optimization of the formula system.

FAQ

Q1: Are you a manufacturer or trading company?

A: Manufacturer.

Q2: What are your terms of payment?

A: Accept LC, TT, West Union Payment. Others can be negotiated.

Q3: What are your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4: How about your delivery time?

A: The goods would be shipped within 5 days if stock is available. We confirm the delivery date according to your order if the stock is not enough.

Q5: Can you provide samples for free?

A: Allowed. We provide free samples, buyers pay for freight.

About Us

Hebei Yida Cellulose Co., Ltd. is a comprehensive enterprise integrating scientific research, production, sales, and after-sales. We mainly produces hydroxypropyl methyl cellulose (), hydroxyethyl methyl cellulose () and redispersible latex powder (VAE) and other products. The professional R&D team independently researches and develops high-stability and super-quality product formulas based on customer geographical differences, industry differences, product differences, and other factors. It is equipped with world-class production equipment, uses German horizontal kettle "one-step" production technology, and fully automated production lines. , Implement a complete and strict production testing process to ensure that the product quality tends to the international level. The annual output of Yida cellulose (HPMC, HEMC) can reach 15,000 tons, and the annual output of redispersible rubber powder can reach 16,000 tons. In 2010, it passed the ISO9001: 2008 quality system certification.