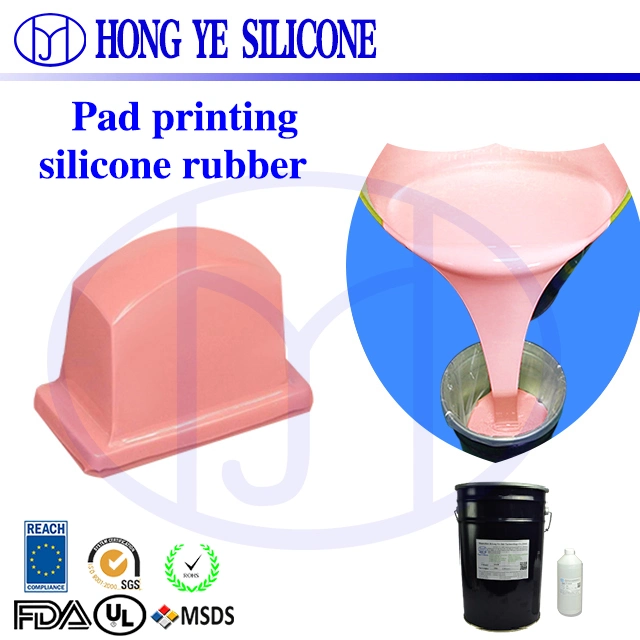

HIgh Quality Liquid RTV2 Silicone Rubber for Making Silicone Pad Printing

Liquid Silicone Rubber for Pad Printing application:

Liquid Silicone Rubber for Pad Printing is mainly applicable to making pads for plastics toys, electroplating products, electronic toys, trademarks and irregular pattern printing. Pad printing pads is a carrier which transfer printing the patterns on the steel plate onto the toy products' surface.

Liquid Silicone Rubber for Pad Printing description:

Liquid Silicone Rubber for Pad Printing with the advantages of abrasion resistance, high temperature resistance, good printing effect, etc., which made of top-quality raw material due to adding American Dupont Teflon high-temperature resistance new material, is processed through high-temperature machining.

Liquid Silicone Rubber for Pad Printing features:

Liquid Silicone Rubber for Pad Printing is mainly applicable to making pads for plastics toys, electroplating products, electronic toys, trademarks and irregular pattern printing. Pad printing pads is a carrier which transfer printing the patterns on the steel plate onto the toy products' surface.

Liquid Silicone Rubber for Pad Printing description:

Liquid Silicone Rubber for Pad Printing with the advantages of abrasion resistance, high temperature resistance, good printing effect, etc., which made of top-quality raw material due to adding American Dupont Teflon high-temperature resistance new material, is processed through high-temperature machining.

Liquid Silicone Rubber for Pad Printing features:

- The liquid silicone very delicate without any impurities or particles.

- Excellent resilience, flexible

- Durable, the printing times can more than 10000 times

- Good oil absorption effect

- The pattern is printed with great clarity and completeness.

- Keep good quality even though 200%-300% silicone oil added

Operation instructions:

Step 1:

prepare all the tools like the pad mold, a cup for mixing, and a glass stick. Clean the pad mould with detergent, and dry the pad mould with an air-gun or cloth, then brush a lay of mold release agent.

Step 2:

Generally, the ratio of pad printing silicon rubber and the silicon oil depends on the size of pattern which customer needs to print. The larger the pattern is, the softer the printing pad should be, and more silicon oil needs to add. Contrarily, if a silicon pad with high hardness needed, silicon oil should be added less or none. General hardness of the printing pad is 15A°~-25 A°. If too much silicon oil added in the silicon rubber, the printing pad will be too soft, and this will limit the printing times. For silicon oil will destroy the molecular chain of the silicon rubber, no matter how supreme quality the silicon rubber is. And therefore, the printing pad will be abrasion intolerant and solvent intolerant and easy aging.

Step 3:

General mixing proportion is as follows: add 30g silicon oil into 100g silicon then hardness of 20A° printing pad we get, which is suitable for the pad printing for alloy car and other products with small patterns and contact areas. If a big contact surface or a soft silicon pad needed, the mixing proportion between the silicon and the silicon oil can be 100:30-100:50. But please note that the more silicone oil added, the softer the silicon pad will be, which will also reduce printing times, abrasion resistance and solvent resistance. Therefore, cost increase and material waste will occur.

Step 4:

Relation between the amount of the curing agent added and the chemical reaction of the silicon is as follows: mix 100g silicon and 30g silicon oil sufficiently and evenly, then add the curing agent which is 2%-3% of the total weight of the silicon and the silicon oil, keep stirring for 2-3 minutes, and then deair to remove the air bubbles. It is better to finish deair within 10 minutes. For if it takes too long, it may cause fast curing and affect the quality of the printing pad.

Advantages of Hong Ye Silicone

Any questions about silicone rubber pls fell free to contact Jelly~

Whatsup;00 86 18938867561

Step 1:

prepare all the tools like the pad mold, a cup for mixing, and a glass stick. Clean the pad mould with detergent, and dry the pad mould with an air-gun or cloth, then brush a lay of mold release agent.

Step 2:

Generally, the ratio of pad printing silicon rubber and the silicon oil depends on the size of pattern which customer needs to print. The larger the pattern is, the softer the printing pad should be, and more silicon oil needs to add. Contrarily, if a silicon pad with high hardness needed, silicon oil should be added less or none. General hardness of the printing pad is 15A°~-25 A°. If too much silicon oil added in the silicon rubber, the printing pad will be too soft, and this will limit the printing times. For silicon oil will destroy the molecular chain of the silicon rubber, no matter how supreme quality the silicon rubber is. And therefore, the printing pad will be abrasion intolerant and solvent intolerant and easy aging.

Step 3:

General mixing proportion is as follows: add 30g silicon oil into 100g silicon then hardness of 20A° printing pad we get, which is suitable for the pad printing for alloy car and other products with small patterns and contact areas. If a big contact surface or a soft silicon pad needed, the mixing proportion between the silicon and the silicon oil can be 100:30-100:50. But please note that the more silicone oil added, the softer the silicon pad will be, which will also reduce printing times, abrasion resistance and solvent resistance. Therefore, cost increase and material waste will occur.

Step 4:

Relation between the amount of the curing agent added and the chemical reaction of the silicon is as follows: mix 100g silicon and 30g silicon oil sufficiently and evenly, then add the curing agent which is 2%-3% of the total weight of the silicon and the silicon oil, keep stirring for 2-3 minutes, and then deair to remove the air bubbles. It is better to finish deair within 10 minutes. For if it takes too long, it may cause fast curing and affect the quality of the printing pad.

Advantages of Hong Ye Silicone

- 21 years rtv2 silicone factory

- Exported since 2006

- Exports to 138 countries

- 14 years on alibaba.com, 12 years on made-in-china.com, a trustworthy company

- 12 experts of R&D, QC staffs

- 6000 square meter factory

- Free training of silicone technique

- Free silicone samples

- Return and exchange are accepted while quality problems occurred

Any questions about silicone rubber pls fell free to contact Jelly~

Whatsup;00 86 18938867561